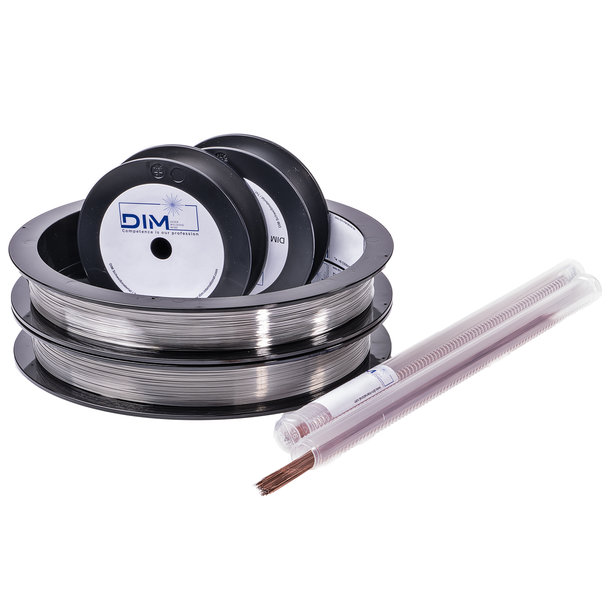

DIM-L-210-Co

Welding wire DIM L-210 Co

Description:

Super alloy/high-performance material

CoCrNiMo

Characteristics:

high resistance to wear

high toughness

high tensile strenght

high ductility

high elasticity

high material fatigue resistance

high chem. corrosion resistance

reverse bending resistance

abrasion resistant

good sliding properties

Characteristics

non-magnetic

highly polished

cold hardening

Tensile strength Rm N/mm²: up to 1110

yield strength N/mm²: up to 734

Elongation: 43 %

thermal conductivity W/mK: 12.5

Hardness of pure laser welding wire: approx. 36 HRC

up to 45 HRC (solidified)

Fields of application:

In molds and mechanical engineering:

Hot runner nozzles (high stability times),

partially against extreme wear,

gg. chem./electrochem. corrosion.

Large range of applications including:

press-/ acid- and steam valve,

valve seats,

shut-off and throttling valves,

chemical filter, seals,

oil industry, aerospace,

engine components, flexure,

torsion spring, investment casting parts CoCr,

forge alloy CoCr, alloy out CoNiCrMo and

CrNiWCo – L605, Gas pressure measuring device

and much more.

- Australia

- Germany

- Switzerland

- Austria

- Argentina

Welding wire DIM L-210 Co

Description:

Super alloy/high-performance material

CoCrNiMo

Characteristics:

high resistance to wear

high toughness

high tensile strenght

high ductility

high elasticity

high material fatigue resistance

high chem. corrosion resistance

reverse bending resistance

abrasion resistant

good sliding properties

Characteristics

non-magnetic

highly polished

cold hardening

Tensile strength Rm N/mm²: up to 1110

yield strength N/mm²: up to 734

Elongation: 43 %

thermal conductivity W/mK: 12.5

Hardness of pure laser welding wire: approx. 36 HRC

up to 45 HRC (solidified)

Fields of application:

In molds and mechanical engineering:

Hot runner nozzles (high stability times),

partially against extreme wear,

gg. chem./electrochem. corrosion.

Large range of applications including:

press-/ acid- and steam valve,

valve seats,

shut-off and throttling valves,

chemical filter, seals,

oil industry, aerospace,

engine components, flexure,

torsion spring, investment casting parts CoCr,

forge alloy CoCr, alloy out CoNiCrMo and

CrNiWCo – L605, Gas pressure measuring device

and much more.

- Australia

- Germany

- Switzerland

- Austria

- Argentina