AL-S2

Laser welding wire AL-S2

Description:

EIN EN 14700: S Fe 8

DIN 8555: WSG 3-GZ-55-ST

Shielding gas wire made of copper-plated MAG wire, cold-drawn, for high-temperature surfacing on hot and cold work tools.

Area of application:

For surfacing of higher hardness on hot and cold work tools that are heavily loaded by pressure and abrasion as well as moderately by impact. Well suited for armoring on unalloyed or low-alloy steel.

Analysis for reference values in %:

| C | Si | Mn | Cr | Mo | Ti | Fe |

| 0.35 | 0.3 | 1.2 | 7.0 | 2.0 | 0.3 | Rest |

Stoffwerte:

| Hardness untreated | 600 – 700 HV10 |

| Soft annealed at 820 °C | approx. 235 HB |

| Hardened 1050 °C in oil | approx. 58 HRC (650 HV10) |

| Tempered 600 °C | approx. 53 HRC |

Processing instructions

Excellent for edge surfacing, but also for surfaces subject to increased wear. On larger areas, we recommend a buffer layer with AL-SNI10, AL-S3, or AL-SCo12. The wire can sometimes be used successfully if AL-S3 and AL-SCo12 break. Relatively low light reflection. Avoid smoothing, if possible. Preheating up to 400 °C and subsequent annealing at approx. 550 ° C is desirable, but not absolutely necessary, especially for minor surfacing, e.g., with a laser.

We recommend the processing take place under shielding gas argon 4.6 or higher. This information is based on our experience, for the correctness of which we cannot be held liable, however. For special usage purposes, e.g., subsequent processing methods, we recommend first carrying out a test on a similar workpiece.

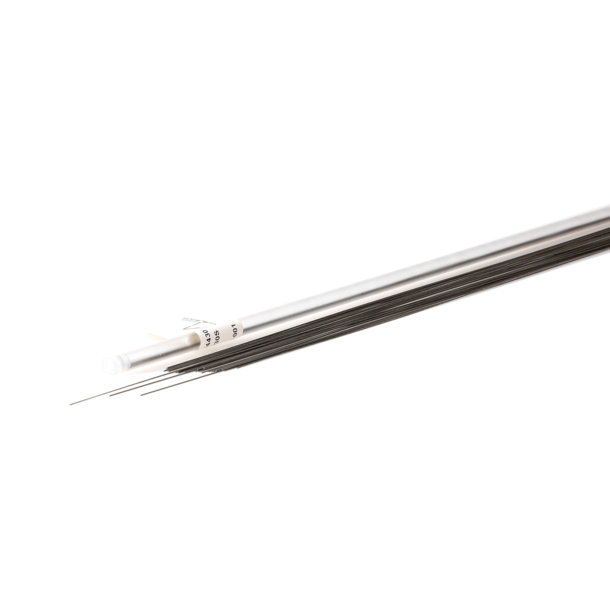

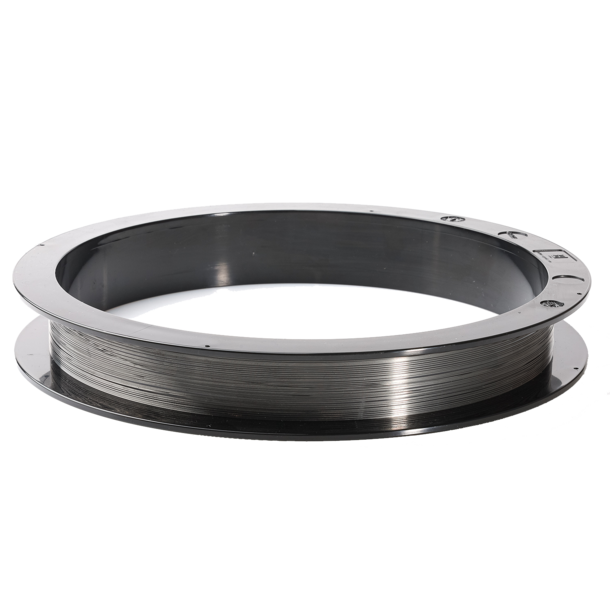

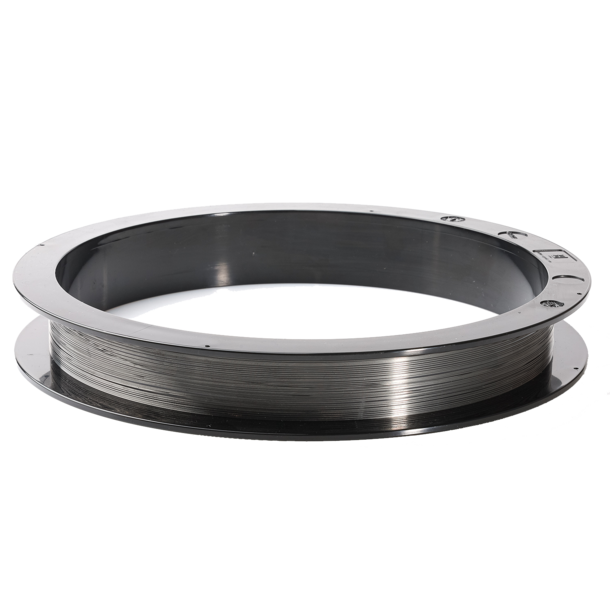

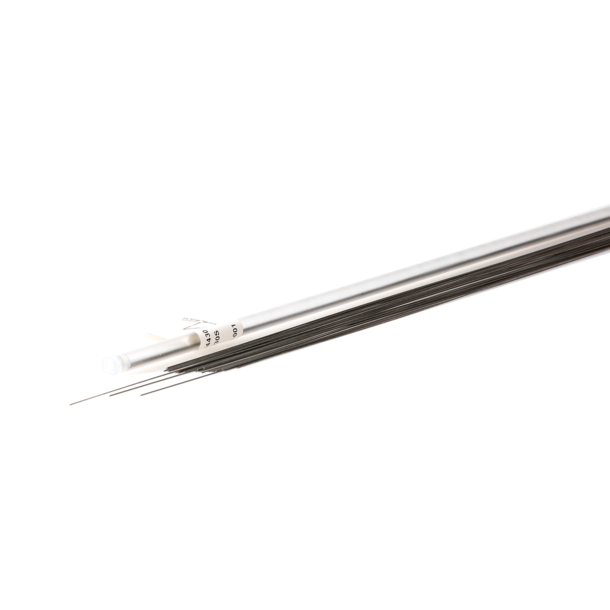

Delivery form

Aligned meter rods from 0.20 to 0.60 mm

Spool 50 m 0.25 to 0.80 mm

Spool 100 m 0.25 to 0.80 mm

Spool 1 kg 0.25 to 0.80 mm

- Australia

- Germany

- Switzerland

- Austria

- Argentina

Laser welding wire AL-S2

Description:

EIN EN 14700: S Fe 8

DIN 8555: WSG 3-GZ-55-ST

Shielding gas wire made of copper-plated MAG wire, cold-drawn, for high-temperature surfacing on hot and cold work tools.

Area of application:

For surfacing of higher hardness on hot and cold work tools that are heavily loaded by pressure and abrasion as well as moderately by impact. Well suited for armoring on unalloyed or low-alloy steel.

Analysis for reference values in %:

| C | Si | Mn | Cr | Mo | Ti | Fe |

| 0.35 | 0.3 | 1.2 | 7.0 | 2.0 | 0.3 | Rest |

Stoffwerte:

| Hardness untreated | 600 – 700 HV10 |

| Soft annealed at 820 °C | approx. 235 HB |

| Hardened 1050 °C in oil | approx. 58 HRC (650 HV10) |

| Tempered 600 °C | approx. 53 HRC |

Processing instructions

Excellent for edge surfacing, but also for surfaces subject to increased wear. On larger areas, we recommend a buffer layer with AL-SNI10, AL-S3, or AL-SCo12. The wire can sometimes be used successfully if AL-S3 and AL-SCo12 break. Relatively low light reflection. Avoid smoothing, if possible. Preheating up to 400 °C and subsequent annealing at approx. 550 ° C is desirable, but not absolutely necessary, especially for minor surfacing, e.g., with a laser.

We recommend the processing take place under shielding gas argon 4.6 or higher. This information is based on our experience, for the correctness of which we cannot be held liable, however. For special usage purposes, e.g., subsequent processing methods, we recommend first carrying out a test on a similar workpiece.

Delivery form

Aligned meter rods from 0.20 to 0.60 mm

Spool 50 m 0.25 to 0.80 mm

Spool 100 m 0.25 to 0.80 mm

Spool 1 kg 0.25 to 0.80 mm

- Australia

- Germany

- Switzerland

- Austria

- Argentina