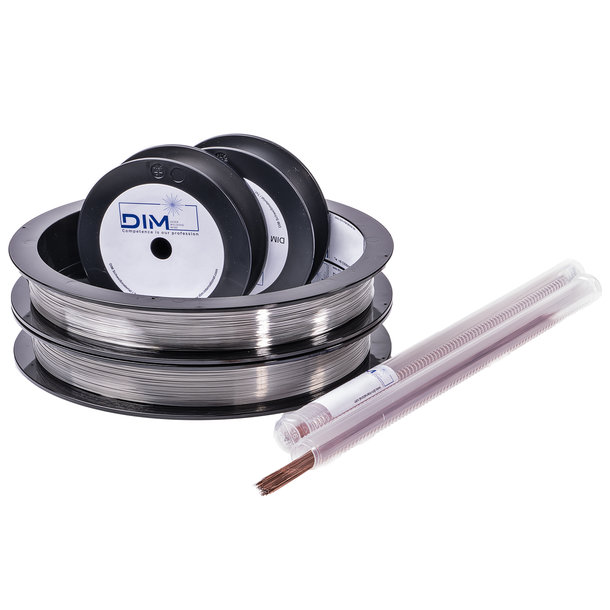

DIM-L-9

Welding wire DIM L-9

Description:

Special alloy

Characteristics:

Hardness of the pure weld material on hardening steels: Approx. 27-38 HRC.

Tensile strength after drawing, depending on wire diameter: > 900-1200 N/mm².

Hardenable to approx. 60 HRC

Operating temperature: 600-650° C

Increased tensile strength and purity

Fields of application:

1.1730/C 45 / IMPAX, HOLDAX, 13 CrMo 4 to 42 CrMo 4,

20CrMo12 / AISI / SAE / ASTM : 4140 / 1.2311/12, 1.2162, 1.2738, 1.2764/67, 1.7218, 1.7225, 1.7227,

1.7335/37/50/54/57/59/73/76/81, 1.7380 (steel and cast), 1.8075, TOOLOX 33 or P20

- Australia

- Germany

- Denmark

- Switzerland

- Austria

- Argentina

Welding wire DIM L-9

Description:

Special alloy

Characteristics:

Hardness of the pure weld material on hardening steels: Approx. 27-38 HRC.

Tensile strength after drawing, depending on wire diameter: > 900-1200 N/mm².

Hardenable to approx. 60 HRC

Operating temperature: 600-650° C

Increased tensile strength and purity

Fields of application:

1.1730/C 45 / IMPAX, HOLDAX, 13 CrMo 4 to 42 CrMo 4,

20CrMo12 / AISI / SAE / ASTM : 4140 / 1.2311/12, 1.2162, 1.2738, 1.2764/67, 1.7218, 1.7225, 1.7227,

1.7335/37/50/54/57/59/73/76/81, 1.7380 (steel and cast), 1.8075, TOOLOX 33 or P20

- Australia

- Germany

- Denmark

- Switzerland

- Austria

- Argentina